Cp, Cpk, Cm, Cmk, control limits - Statistical Process Control

A high Cmk index means, then, that you have a good machine with a small spread in relation to the tolerance width, and also that it is well centred within that width. If Cmk is equal to Cm, the machine is set to produce exactly in the middle of the tolerance range (see Fig. 2).

Machine Capability Index - What is Six Sigma

Machine capability index is an index derived from the observations from uninterrupted/continuous production run. It is often known as Cmk. It is a short-term capability index and also called initial process capability. The long-term capability index can be calculated for a machine/process after achieving the required Cmk value.

Cm Cmk - Machine Capability, formulas and recommendations

Jan 25, 2025 · Cmk. Cmk represents machine capability considering shifts toward one of the specification limits. For this metric, two separate calculations are performed, and the smaller result is taken. The formula for Cmk (for normal distribution): where: USL - Upper Specification Limit; LSL - Lower Specification Limit; X̄ - Process mean; σ - Standard ...

Machine Capability Index (CMK) - Lean Six Sigma Glossary Term

The Machine Capability Index (Cmk) is an essential tool in manufacturing. It ensures machines produce high-quality products consistently. By understanding and monitoring Cmk, manufacturers can identify issues, make necessary adjustments, and improve overall efficiency.

Cmk - machine capability index - Six-Sigma-Material.com

To help understand Cm, if the Cm value is 2.0, that means the spread of the consecutive measurements will fit 2x into the tolerance width. The tolerance width is two as big as the data spread. The tolerance range is the range between the Lower Specification Limit (LSL) and the Upper Specification Limit (USL).

Machine Capability Index: A Tool for Authentication and Verification

Oct 23, 2024 · Cmk is a short-term index for measuring machine capability. It allows for an overview of how a machine is performing in your workflow. Cmk only considers two factors when you calculate it, making it useful for ascertaining if it is performing as intended.

Cmk!! How Could There Possibly Be Another Capability Index??!!

Regardless of the abbreviations, all capability indices are based on the following general formula: Process Capability = Specification Range / Process Range. The specification range is generally fixed and provided on the prints or engineering specifications for the part being produced.

Cm - Machine Capability - Six-Sigma-Material.com

Cm and Cmk are two denotations that represent machine capability. Cm represents a very short term reflection of machine performance in relation to the size (i.e width or range) of the tolerance limits (or specification limits). Higher values for Cm …

Tracking Machine Improvements with Machine Capability Index

Feb 18, 2025 · Many people sometimes confuse Cmk and Cpk. An easy way to distinguish the two is to remember the ‘M’ in Cmk lets you know that it is the Machine Capability Index and the ‘P’ in Cpk lets you know that it is the Process Capability Index. Overview: What Is a Machine Capability Index?

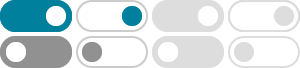

Cm Cmk or SPC - Atlas Copco

Jul 23, 2021 · To have accurate Cm/Cmk values, usually, about 20 to 25 rundowns are needed. This is only possible if the tool is not used continuously on a production line. Typically, Cm/Cmk tests are done before a tool is assigned to an application in the manufacturing process or after service or a repair.