What sheet metal shops wish you knew: Hems, jogs, and forming tools

Aug 16, 2017 · A jog bend is simply a pair of equal and opposite bends closely spaced to create a lazy Z offset, which is often equal to the material thickness. This makes for a nice fit and finish with a mating cover, perhaps.

What is A Joggle In Sheet Metal - MIHARMLE

Joggle is a small offset bend less than 90 degrees. During joggling, one sheet surface goes down due to applied force. The other side slightly goes up from the plane. Both surfaces change from up to down, which is 100% equal. This slight bend or step connects and overlaps two sections of metal sheets. Let me explain this with an example.

What is a Joggle In Sheet Metal - Sheet Metal Fabrication Machine ...

Apr 28, 2024 · A joggle in sheet metal is a small offset or bend to create an overlapping joint on a flush surface. The offset bending process creates two opposite bends with equal angles in a single action. The joggle bends are in opposite directions and less than 90°.

Jog Bends - Protocase

Jog bends are a more manual method of achieving parallel distances, and enable larger distances than material offset bends. Jog bends offer greater flexibility as you are not limited by the single tool and operation.

Offset Tool – SheetMetal.Me

Offset tooling allows two v bends to be formed closer together than regular Press Brake Dies would allow. This creates a z shaped profile in the sheet metal. This type of bend is also commonly referred to as a jog. The two basic forms of offset tooling are …

Sheet Metal Hem: The Complete Guide - KDM Fabrication

While sheet metal jog is just a pair of equal and opposing bends placed closely together to produce a sluggish Z offset that is frequently equal to the thickness of the material, it results in a beautiful fit.

What’s Sheet Metal Hemming? Process, Uses, and Tips

May 5, 2024 · On the other hand, a jog (or joggle) involves creating two opposing bends close together in the sheet metal, resulting in a Z-shaped offset that facilitates the assembly of parts. Hem’s purpose is edge durability and appearance, while jogs improve the assembly and fit of metal components.

Different Types Of Bends - Protocase

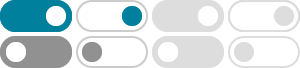

While jog bends and material offset bends achieve a similar result, the bending process for each is different. Material offset bends are performed in a single operation, while jog bends are performed in two separate operations.

Sheet Metal Hemming: Complete Guide & Tips

Aug 31, 2024 · A jog is a small, localized bend, while a hem refers to folding the sheet edge back onto itself. Jogs are often used in applications where a small offset is needed, like making complex shapes or accommodating hardware.

Sheet Metal Hemming: Process, Methods, and Tips - ProleanTech

Jun 21, 2024 · On the other hand, sheet metal jogging involves two symmetrical bends placed side by side to create a mild Z offset. The thickness of the material used is the same as that of the channel formed, thus a close fit.